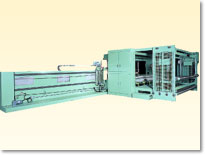

| *SPECIAL FINISIHING MACHINE HEAT-THROUGH |

|

[FEATURE]

*Unique side open construction.

*Heat distribution is uniformed for all direction (Three dimension).

*Product thickness can be set freely.

*Air-through direction can be chosen freely in the design stage.

.The extension comparatively easy.

[SPECIFICATION]

Machine working width:3,600[mm],Machine speed:-15[m/min],Temperature:80-250C(MAX.)

Heat source:GAS,steam,beat medium circulating

[USING FOR VARIOUS PURPOSES]

*Thermal-bonding;

.Insulator interior for cars,Drying forming Pulp,Sleepware and Filter.

*Heat treatment;

.Interior materials,Civil engineering fabrics and special grassfiber.

[THE EXAMPLE OF CONBINATION]

*HEAT-THROUGH"+Cooling+Winder

*HEAT-THROUGH"+Calender+Cooling+Winder

*HEAT-THROUGH"+Calender+Cooling+Cutter

*HEAT-THROUGH"+Cooling+Cutter

*HEAT-THROUGH"+Laminating+Calender

.+Cooling+Winder

|

| *RELAXING TYPE HOT AIR DRYER |

|

[FEATURE]

Fabrics is dried with no-tension and forced air-beating.

This drying system gives excellent shrinkage and relaxing effects and resulting a luxuriously soft bulky finish.

Non-dry seat, which makes free condition, is passed between the upper and lower special heat^resistant net conveyors, and beated by the forced hot air beating, there for non-dry seat are treated without applying tension to either its length or width.

[MAIN SPECIFICATION]

1.Working width:3000mm[MAX]

2.Speed:100m/min (Note:Drying speed depends on drying condition)

3.Number sources:2-4 chamber

4.Heat sources:Steam

5.Dry(treatment)temperatures:100-130C

|

| *AUTOMATIC WINDER WITH ACCMULATOR |

|

[FEATURE]

1.Automatic operations such as winding core supply,winding doffing and cutting are perfectly performed by this winder.

2.If you use as In-Line Winder,it can attache Accumulator for timely,Synchronized speed control for preceding machine and Winding tension controller.

3.Option:SlitterkCrush cutter or Shear cutterlDegital type length counter,Winding core pull out device,Trim ribbon winder.

[MAIN SPECIFICATION]

1.Working width:2000-5000mm

2.Winding Dia:Max 1500mm

3.Speed:Max.80m/min

|

| *ROTARY SCREEN PRINTER |

|

[FEATURE]

This machine is compact type rotary type screen printer and can get high productivity.

This machine performs non-distortion and high accuracy printing by means of Adoption both ends driving.

Easy fitting and removing of screen & aqueegee.

Simple design,easy maintenance.

[USES]

1.processing of nonwoven fabrics,

2.anti-slip finishing,

3.printing of paper,films and fabrics,

4.coating,etc.

[SPECIFICATION]

Machine working width:1,000-2,200[mm]

Repeat Length:640[mm]

Machine speed:5`50[m/min]

|

| *DISPERSION DOT COATING PLANT |

|

[FEATURE]

1.The Dispersion dot coating can give to your products the high quality and "soft to the touch" that the Scatter process or the Powder dot process can not never give.

2.You can easy oprate with high accuracy and stability.

3.We have several type of dot pattern that you can select and get as the cylinder at low cost.

[MAIN SPECIFICATION]

1.Processing working width:MAX.1300mm

2.Processing speed:MAX.40m/min.

|

| *SPECIAL FINISHING COMFIT MACHINE |

|

"FOR OBTAINING ELASTICITY,SOFT HANDLING OR ANTI SHRINKING"

COMFIT MACHINE,is a machine developed by UNITIKA LTD,UENOYAMA KIKO CO.,LTD and KINYOSHA CO.,LTD, after many years of joint researches and development.

This machine is able to provide fabrics with new characteristics to woven and knitted fabrics.

1)Improving soft and elegant handling

2)Giving anti-shrink finish and high elasticity

3)Giving soft luster

4)Suppressing nep

5)Giving crease

6)Suppress needle holes

COMFIT is designed for adding high value on non-woven fabric.

You can perform innovation by using this machine in your market.

[OPTION]

OPERATION PANEL

1.Interactive Operation through the Built-in Computer of pictographic symbols:You can grasp the operation control at a grance and can easily operate the machine so that operation errors can be minimized.

2.Mode Operation of product code for 60 Patterns Possible:The operating parameter are automatically set ensuring constant quality and exact reproducibility,safely and reliable.

3.The self-diagnosis function and maintenance information function provides graphic display which makes maintenance check easy.

4.The language which is used for the display can be selected [e,g,Japanese,English,Chinese,Indonesian,Thai].

|

| *FELT CALENDER |

|

[FEATURE]

1.This machine introduce fabrics the low tension as supplying humidity with steam and insert the felt and press good handing.

2.Suppressing nep smoothing of surface.

3.Shirinkage effect and desity-up,smoothing(surface).

[MAIN SPECIFICATION]

1.Working WIdth:1000-3000mm

2.Speed:Max.50m/min

3.Roll Dia: 610mm

|

|